Business

Business Recycle

Recycle

- Recycle Business

- Flake Productions

- Pellet Productions

- Certifications and Sales

Business Overview

ReNA is a leading domestic company specializing in the production of high-quality rPET flakes and pellets. To meet the growing demand for sustainable materials, ReNA utilizes cutting-edge facilities and technologies to stably supply food-grade rPET to both domestic and global clients.

2018 year

Established

120K t/year

[Flake] Production Capacity

20K t/year

[Pellet] Production Capacity

Affiliates

(Members of ReNA)

8 Sorting Centers

- Located in high PET-yield metropolitan areas for stable production capacity

MR Subsidiaries

(Members of ReNA)

Flake/Pellet production sites

Export History(‘24)

Flake 7,000 tons

>Pellet 9,000 tons

- Ongoing exports of flakes and pellets to clients in Europe, the United States, and Southeast Asia

Certifications & Patents

Widely Certified

- GRS & ISCC Plus

- ISO 14001/9001/45001

- FDA & Korean MFDS certification for food-grade rPET

- 3 registered patents

Value chain Integration Status

Integrating the full process, from sourcing recycled materials to manufacturing premium-quality rPET.

-

Sorting Centers

self-operated

sorting centers in

the Seoul

Metropolitan area -

Flake Production

Runs the largest

flake production

facility in Korea

(120K t/year ) -

Pellet Production

Owns the Korea's

first food-grade

certified pellet

facility -

ReNA oversees the full value chain, from PCR collection to rPET production, ensuring operational stability and quality assurance.

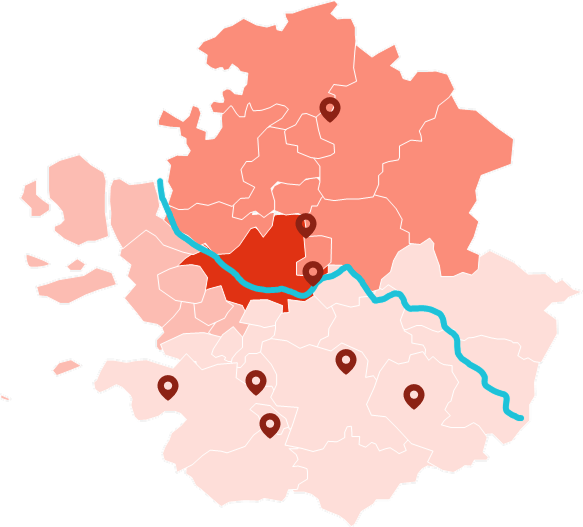

ReNA Site location

ReNa operates an integrated rPET processing network centered in the Seoul metropolitan area.

Sorting Centers, Flake & Pellet Production Facilities

Seoul Northern Gyeonggi Western Gyeonggi Southern Gyeonggi

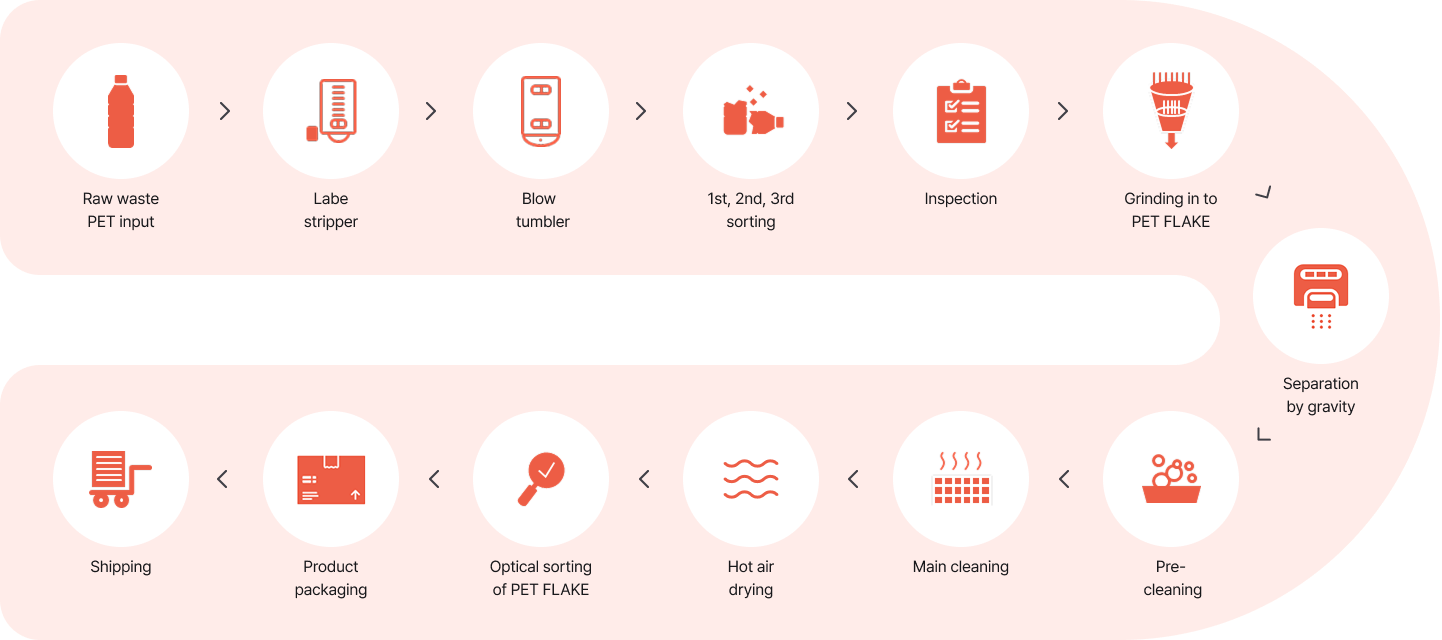

Flake Production Process

ReNA(RM), Korea’s largest rPET flake producer, ensures stable production of high-purity, high-quality flakes through a 3–4 stage sorting process using optical sorters and skilled personnel, followed by 5–6 dewatering cycles.

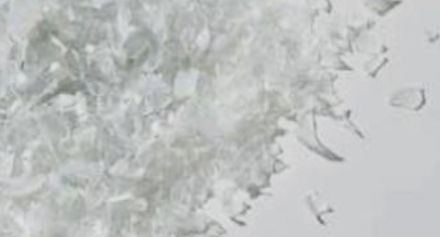

Product

RM produces a wide range of PET flakes optimized for various end-use applications and specifications, offering customized products tailored to specific client needs.

High Quality flake

![]()

PTC

R-chip for food

containers

![]()

PTM

Sheets, trays

![]()

PTCM

R-chip for PET bottles

![]()

PB

fiber(staple fiber), filling materials (beddings, padded clothes)

![]()

TRAY

Staple fiber sound absorbing materials, non-woven fabrics

![]()

SKY

sheets, trays, staple fiber

![]()

BROWN

Staple fiber-sound absorbing materials, non-woven fabrics

| Property | Unit | PTCM | PTC | PTM | PB |

|---|---|---|---|---|---|

| Content of label and other visible contaminants |

ppm | 200 Max. | 200 Max. | 1,000 Max. | 2,000 Max. |

| PO and Adhesives (Glue, Yellow Flake) | ppm | 1,500 Max. | 1,500 Max. | 1,500 Max. | 2,000 Max. |

| PVC | ppm | 30 Max. | 30 Max. | 30 Max. | 100 Max. |

| Moisture Content | % | 1.0 Max. | 1.0 Max. | 1.0 Max. | 1.0 Max. |

| Intrinsic Viscosity | dl/g | 0.72 Min. | 0.72 Min. | 0.72 Min. | 0.72 Min. |

| ΔpH (Alkalinity) | pH | 0.6 Max. | 0.6 Max. | 0.6 Max. | 0.6 Max. |

| Bulk Density | kg/m³ | 300 Min. | 300 Min. | 300 Min. | 300 Min. |

Application

ReNA (RM) continuously produces high-spec flake products that meet the requirements of both domestic and international clients.

High-quality PET FLAKE

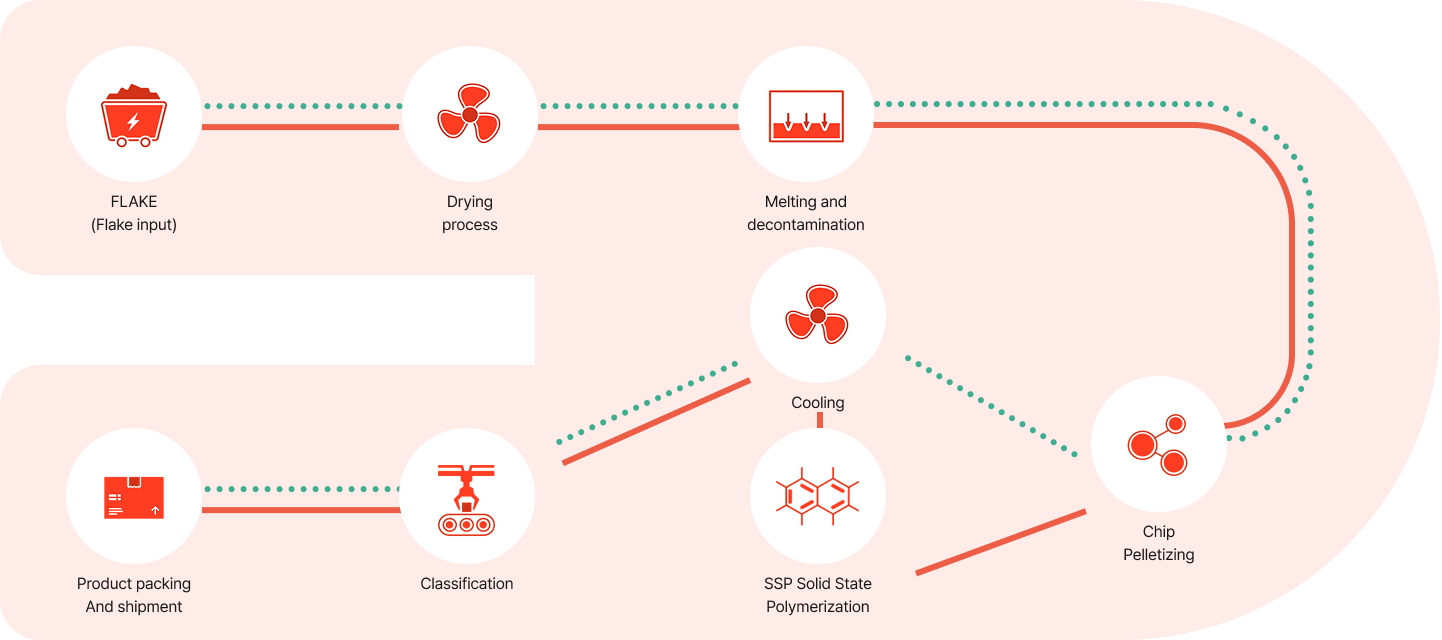

Pellet production process

ReNA(H2), r-chip producer, uses EREMA equipment and a fully integrated process that includes drying, melting, pelletizing, and Solid-State Polymerization(SSP) to stably produce high-quality rPET pellets.

Recycled PET Chip Production

Product

ReNA(H2) produces a diverse range of pellets optimized for various applications and offers customized solutions tailored to customer needs.

B-to-b r-chip (IV 0.80)

| PROPERTY | UNIT | SPECIFICATION |

|---|---|---|

| Intrinsic viscosity | dl/gr | 0.80±0.03 |

| Acetaldehyde | ppm | Max 1 |

| Benzene | ppb | Max 10 |

| Limonene | ng/g | N.D. (<0.5) |

| Moisture | % | Max 0.2 |

| Color - L | - | Min 66 |

| Color - b | - | Max 3 |

| Density | g/cm3 | 1.40±0.01 |

| Melting Point | ℃ | 250±3 |

Filament-use r-chip (IV 0.65)

| PROPERTY | UNIT | SPECIFICATION |

|---|---|---|

| Intrinsic viscosity | dl/gr | 0.65±0.03 |

| Moisture | % | Max 0.2 |

| TiO2 | wt% | 0.3 |

| Color - L | - | 78±4.0 |

| Color - a | - | -2±1.5 |

| Color - b | - | Max 5±2 |

| Chip size | EA/gr | 35±5 |

Application

ReNA(H2) is continuously advancing the development and application of materials for home appliances, automotive electronics, and a wide range of injection-molded products

Certifications & approvals

ReNA is a trusted r-PET specialist with global certifications—including ISO, GRS, FDA — and proprietary technology patents, capable of meeting the stringent quality requirements of global clients.

Flake

- Global Recycled Standard

- ISO 14001

- ISO 9001

- ISCC CERTIFIED

- 식품의약품안전청

Pellet

- Global Recycled Standard

- ISO 14001

- ISO 9001

- ISCC CERTIFIED

- REACH COMPLIANCE

- EUROPEAN FOOD SAFETY

- AUTHORITY

- FDA

Sales

With reliable supply capabilities and high quality, ReNA delivers flakes and pellets to leading clients across Korea and abroad.

We look forward to the opportunity to create sustainable future value together with ReNA.

(Tel) +82 - 31 - 372 - 5144

(Fax) +82 - 31 - 372 - 5174